| |

|

|

| Glycerine Filled Pressure Gauges |

|

| Provides Extra Margin of Protection from Vibration and Pulsation. 'MASS1 make Glycerine Filled Pressure Gauges are installed on Powerpacks, Hydraulic Machinery, Pumps, Compressors, Power Plants, Pipelines and Transmission Stations where Vibration & Pulsation are destructive factors. Glycerine filling makes the difference, the movement is submerged and constantly lubricated. The damaging effect of pulsation and vibration are minimised Pointer flutter is virtually eliminated because both the liquid filling and a restrictor screw in the Socket help in dampening pulsation. |

|

| |

|

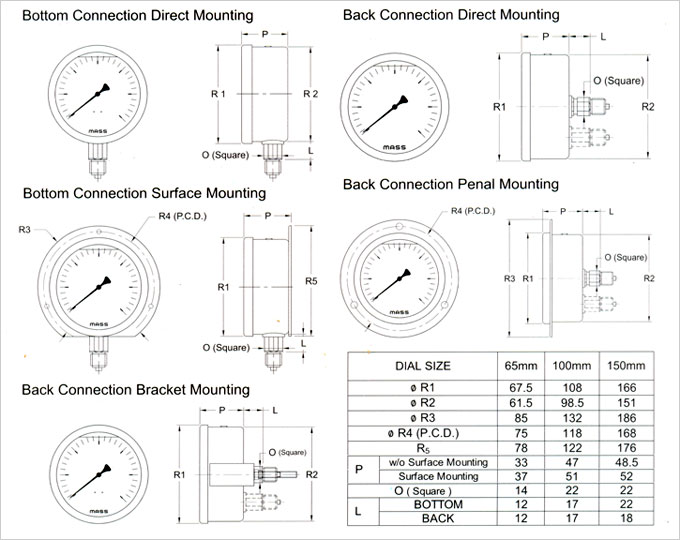

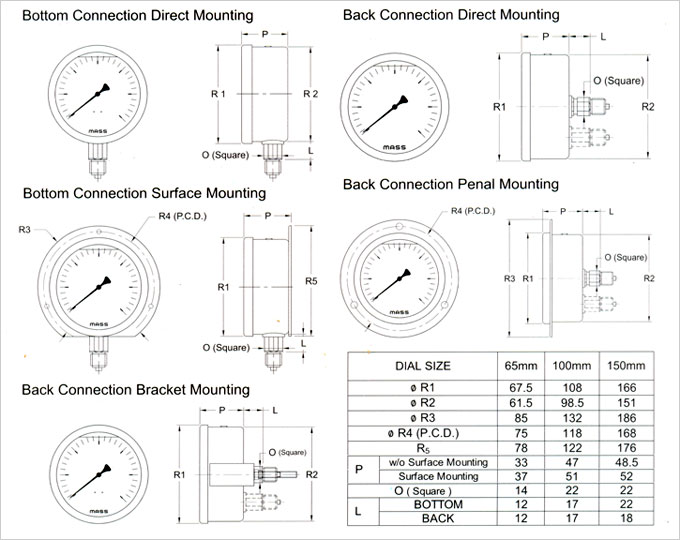

| Note : For dial size 100mm & 150mm Back connection pressure gauges are off center back as per shown Dotted lines in drawing. |

| |

| Specification : |

| Dial Size |

63mm, 100mm & 150mm |

| Accuracy |

+ 2% / + 1% of full scale |

| Bourdon |

BRASS / Phosphor Bronze / SS316 / MONEL |

| Movement |

BRASS / S. S. 304 / S. S. 316 |

| Socket |

BRASS / SS316 / SS316L / MONEL |

| Case & Bezel |

S. S. 304 Crimp type / Snap Action Bayonet type |

| Range |

Pressure up to 1400 kg/cm , Vacuum & Compound Ranges. |

| Joints |

S. S. Bourdon tube tip and the socket ends are ARGON ARC WELDED and phosphor bronze bourdon tubes are silver brazed / soldered. Bourdon tubes are heat-treated and stress relived. |

| Window |

Acrylic glass / Safety glass |

| Mounting |

Direct with bottom entry / Direct with back entry Flush Panel with back entry (Three Panel / Bracket) Surface with bottom entry |

| Thread Connection |

1/8", 1/4", 3/8", 1/2" BSP / BSPT / NPT (M) |

|

All Glycerine filled models models start with suffix "GF". FOLLOW DECODIFICATION SHEET FOR DETAILS. |

| |

|

|